Smarter Laundry Starts Here.

Brands

Electrolux

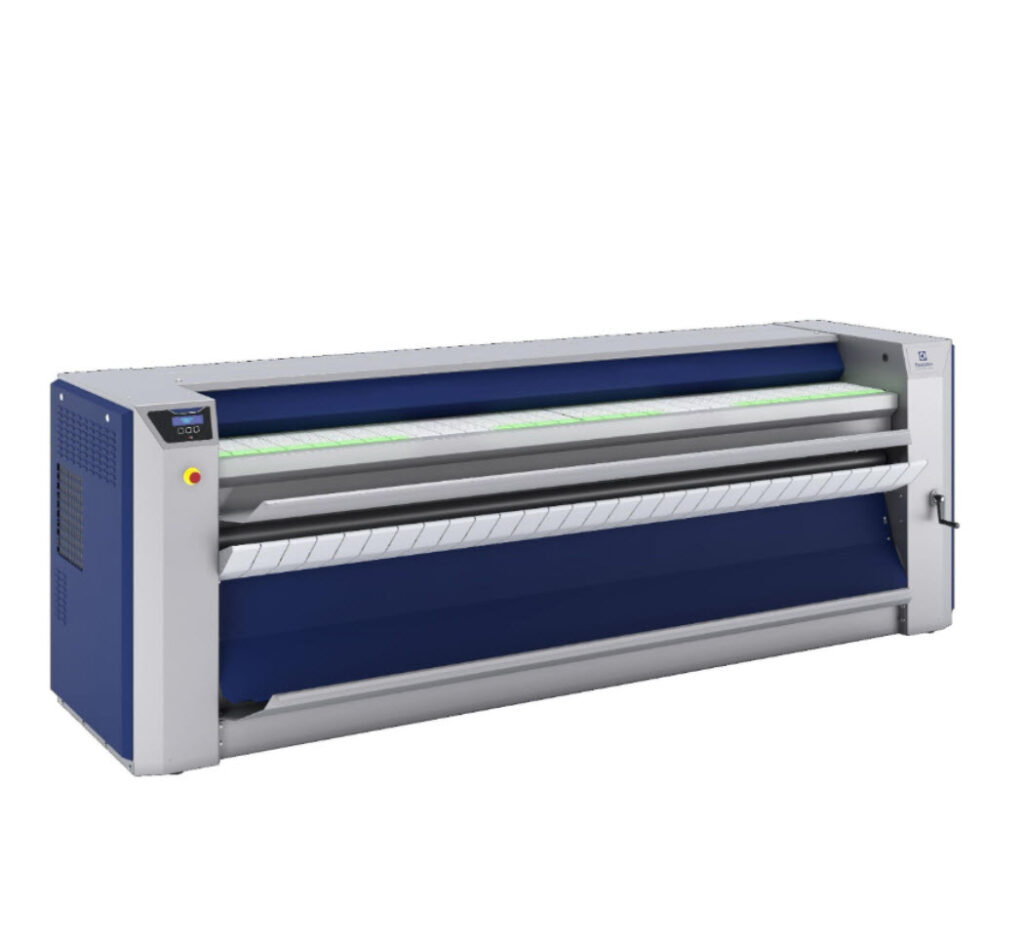

Electrolux Flatwork Ironers are designed to last 30’000 hours, which equates to 8 hours per day for 10 years. They are centred around a great result & minimising labour costs, great for sites processing 15 to 100 KG per hour.

Foltex

Laco Machinery

Laco is our high performance partner for high production & automation, they offer a great selection of flatwork ironers, for sites processing 100 to 1000 kg per hour direct from washer without pre-drying.

Chest vs Cylinder Heated

Our smallest ironer is chest heated for cost efficiency & is a simple solution for a low linen requirement of up to 20KG.

Our medium production flatwork ironers are cylinder heated, they maximise production, while minimising floor space. The contact surface & heat input is superior to small return to operator chest ironers. These are our most popular solutions for small to medium requirements.

Our large output flatwork ironer range are chest heated to minimise energy consumption with production from from 100 to 1000 kg per hour, used in large OPL’s or Central Laundries.

Sizes

Although we offer 1.6 & 2.0 meter widths, linen is generally folded here, unless single sheets are being processed on the 2.0m ironer. This means 1 operator is able to process the linen demand.

Our most popular size are +3.0m meter width, this is due to these ironers mainly processing king linen & no folding is required, thus improving production & results. We can run the ironers faster & with high humidity contents without folding.

The different ironer diameters cater to different evaporation potentials, basically the wider the diameter the higher the production. We can start processing certain linens direct from washer to ironer with 459mm diameters, however 800 to 1200mm we can guarantee direct processing & best labour efficiencies.

Automation

Labour is the biggest cost in laundries operated in New Zealand, around 75% of the cost is associated to this aspect, so we try automate where ever possible.

Ironers can be fitted with automatic feeders to reduce labour from 2 to 1 people, saving around $50’000 per annum.

Ironers fitted with folding & stacking systems again reduce labour from 2 to 0, meaning the person feeding can also manage the stacked linen to store, saving $100’000 per annum.

Automating your ironer can save your business $150’000 per year.

Flatwork Ironers

IB62316

-

Cylinder 1650 x Ø 230 mm

-

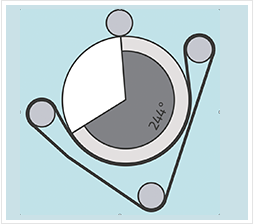

Contact Surface 116 Degrees

-

Prod. p/h 20KG @ 15% RMC

-

Evaporation 6 L p/hour

-

Type Chest Heated

-

Automation None

IC63320

-

Cylinder 2065 x Ø 330 mm

-

Contact Surface 247 Degrees

-

Prod. p/h 40KG @ 25% RMC

-

Evaporation 20 L p/hour

-

Type Cylinder Heated

-

Automation None

IC64832

-

Cylinder 3170 x Ø 549 mm

-

Contact Surface 278 Degrees

-

Prod. p/h 80KG @ 40% RMC

-

Evaporation 60 L p/hour

-

Type Cylinder Heated

-

Automation None

IC64832FLF

-

Cylinder 3170 x Ø 549 mm

-

Contact Surface 278 Degrees

-

Prod. p/h 80KG @ 40% RMC

-

Evaporation 60 L p/hour

-

Type Cylinder Heated

-

Automation Feed & Folding

IV64832FFS

-

Cylinder 3170 x Ø 549 mm

-

Contact Surface 278 Degrees

-

Prod. p/h 80KG @ 40% RMC

-

Evaporation 60 L p/hour

-

Type Cylinder Heated

-

Auto Feed,Fold & Stack

CO833

-

Cylinder 3300 x Ø 800 mm

-

Contact Surface 185 Degrees

-

Prod. p/h 250KG @ 50% RMC

-

Evaporation 125 L p/hour

-

Type Chest Heated

-

Automation Feed,Fold & Stack

D800

-

Cylinder 3300 x Ø 800 mm

-

Contact Surface 185 Degrees

-

Prod. p/h 250KG @ 50% RMC

-

Evaporation 125 L p/hour

-

Type Chest Heated

-

Automation Optional

D1200

-

Cylinder 3300 x Ø 1200 mm

-

Contact Surface 205 Degrees

-

Prod. p/h 400 to 1200KG @ 50% RMC

-

Evaporation 200 to 600L p/hour

-

Type Chest Heated

-

Automation Optional