Smarter Laundry Starts Here.

Woolmark Certified

Electrolux Professional have had their wet cleaning solution certified by the Woolmark Company since 2004 for cleaning Woolmark garments labelled as dry-clean only.

To have achieve this we not only supply washers / dryers / finishing equipment, however we also supply the chemicals needed to maintain certification.

The Hohenstein Institute

Lagoon Advanced Care has been endorsed by the Hohenstein Institute, which tested the effects of both traditional solvent cleaning & Lagoon Advanced Care on delicate garments in laboratory conditions.

After over 10 cleaning cycles, the tests have shown equal or comparable results in terms of textile wear, dimensional change and colour loss.

Washer Benefits

Pro’V’tex

Pro’V’tex uses a pump mounted at the base of the washer to pump water / chemistry from the base to the top of the washer, creating hydraulic action.

This gentle hydraulic action improves delicate cleaning, while improving the load dimensioning from competitors standard 1:20 to 1:13, meaning instead of a 50% load, we achieve a 75% load. This improves the footprint needed for installation, however also means a better extraction of moisture, which leads to less drying time & delicate fabric damage.

Integrated Weighing System

By installing load cells under the drum of washer, we are able to accurately weigh the load, changing chemical dosages accordingly, while improving rinse quality.

The 7 inch touch screen will also show this weight live on the screen, preventing operators from overloading according to manufacturer recommendations based on fabric type, which improves results & reduces skills needed to operated equipment.

Power Balance

A washers greatest stress point is during extraction & wet cleaning does exert additional stresses on the machine due to increased vibration from varied loads & under loading.

This is why Electrolux developed Power Balance, which is a technology that uses an accelerometer to measure vibration, which is then managed live by the washers controller. This ensures the appliance doesn’t reach vibration points which would cause damage, while optimising extraction which reduces dry times.

Dryer Benefits

Moisture Balance

Our third generation moisture management system has been refined & improved over 3 generations of professional dryers, line 4000 / line 5000 / line 6000.

This advanced technology uses conductivity to measure the dampness levels of fabric through the dryers drum, which also carefully monitors the incoming & outgoing temperatures, stopping when dry & minimising the opportunity of over drying, which would cause fabric damage.

Reversing Drum

By redistributing the wet area, this quickens dry times by up to 7 minutes (saving energy), while reducing balling / tangling of larger items.

It costs more to build a dryer with a reversing drum, as we need 2 motors, 1 for drum rotation & 1 for air movement, however the advantage in huge & wouldn’t recommend a non reversing dryer for delicate garments.

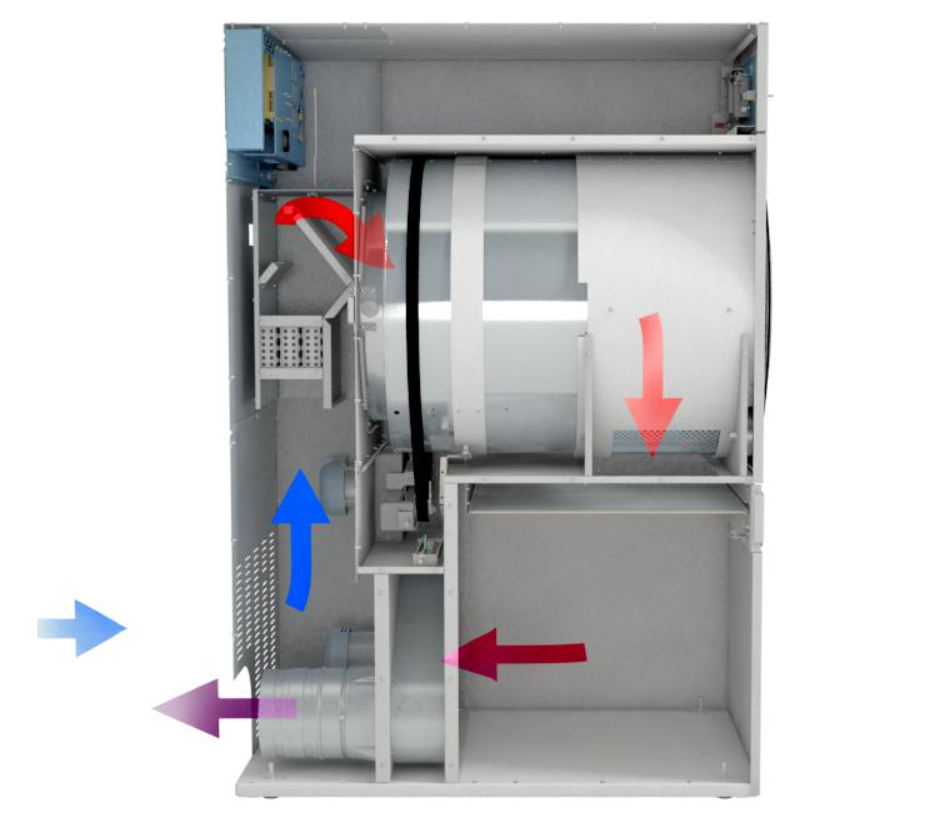

Axial Airflow

Older dryers use a technology called Radial Airflow, which allows the skirting of hot air around the drum, without aiding in moisture removal.

Axial Airflow found in all our LAC approved dryers, prevents skirting & ensures heat generated is used effectively to create evaporation, why our dryers use +20% less energy than most competitors.

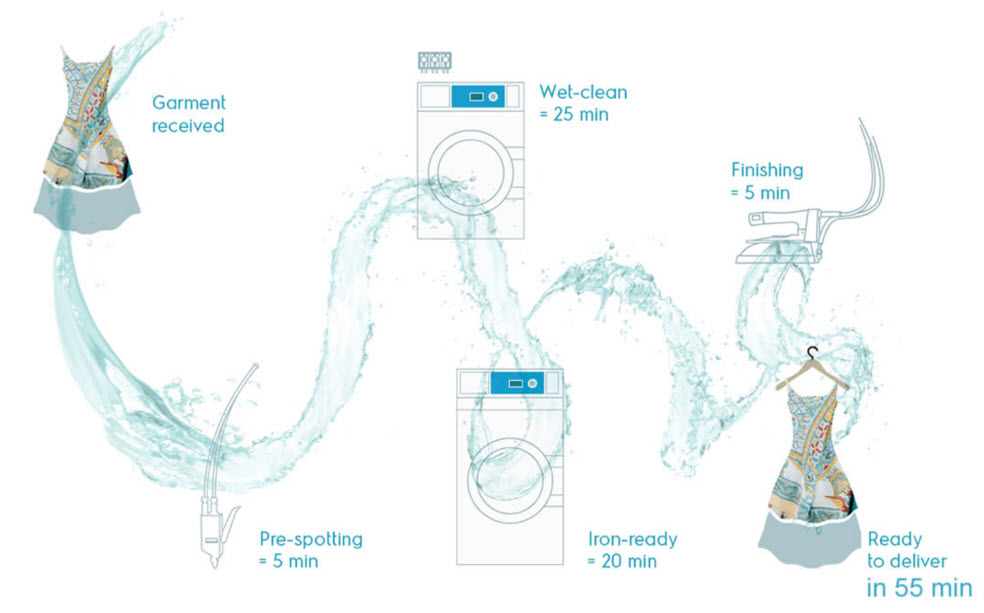

Ironing - Vacuum / Blowing Finishing Table

We supply a range of finishing equipment, as volumes increase we need to automate to reduce labour costs, however initially a professional vacuum & blowing finishing table with a steam boiler is enough.

The vacuum function holds the item in place, so the operator is able to tension the garment & help with moisture removal from the steam ironer.

The blowing function allows the operators to steam fibres without pressing, reducing the risk of shining or burning delicate fibres.

Steam is needed for the hand ironer, we recommend an internal boiler for finishing tables, which automatically refills from the mains & maintains high pressure / dry steam, for best in class finishing at the fastest speeds.

Wet Cleaning & Finishing

WH6-6 LAC

-

Capacity 6 KG

-

Designed Life 30’000 Cycles

-

Accelerometer Yes

-

Pro’V’tex Pump Standard

-

Degree of Loading 1/13

-

Woolmark Certification Yes

TD6-7 LAC

-

Capacity 7 KG

-

Designed Life 30’000 Cycles

-

Reversing Drum Yes

-

Moisture Balance Yes

-

Magnetic Door Lock Yes

-

Woolmark Certification Yes

WH6-20 LAC

-

Capacity 20 KG

-

Designed Life 30’000 Cycles

-

Accelerometer Yes

-

Pro’V’tex Pump Standard

-

Degree of Loading 1/13

-

Woolmark Certification Yes

TD6-20 LAC

-

Capacity 20 KG

-

Designed Life 30’000 Cycles

-

Reversing Drum Yes

-

Moisture Balance Yes

-

Magnetic Door Lock Yes

-

Woolmark Certification Yes

WH6-27 LAC

-

Capacity 27 KG

-

Designed Life 30’000 Cycles

-

Accelerometer Yes

-

Pro’V’tex Pump Standard

-

Degree of Loading 1/13

-

Woolmark Certification Yes

TD6-30 LAC

-

Capacity 30 KG

-

Designed Life 30’000 Cycles

-

Reversing Drum Yes

-

Moisture Balance Yes

-

Magnetic Door Lock Yes

-

Woolmark Certification Yes

WH6-33 LAC

-

Capacity 33 KG

-

Designed Life 30’000 Cycles

-

Accelerometer Yes

-

Pro’V’tex Pump Standard

-

Degree of Loading 1/13

-

Woolmark Certification Yes

TD6-37 LAC

-

Capacity 37 KG

-

Designed Life 30’000 Cycles

-

Reversing Drum Yes

-

Moisture Balance Yes

-

Magnetic Door Lock Yes

-

Woolmark Certification Yes

FSU1

-

Description Spotting Table

-

Usage High - 8 hours per day

-

Boiler 5.0L

-

Refilling Automatic

-

Vacuum Yes

FIT1

-

Description Finishing Table

-

Usage Low - 2 hours per day

-

Boiler 1.8L

-

Refilling Manual

-

Vacuum Yes

FIT2B

-

Description Finishing Table

-

Usage High - 8 hours per day

-

Boiler 5.0L

-

Refilling Automatic

-

Vacuum Yes

FIT2-WC

-

Description Finishing Table

-

Usage High - 8 hours per day

-

Boiler 5.0L

-

Refilling Automatic

-

Vacuum & Blowing Yes